APPLIED MATERIALS, USA

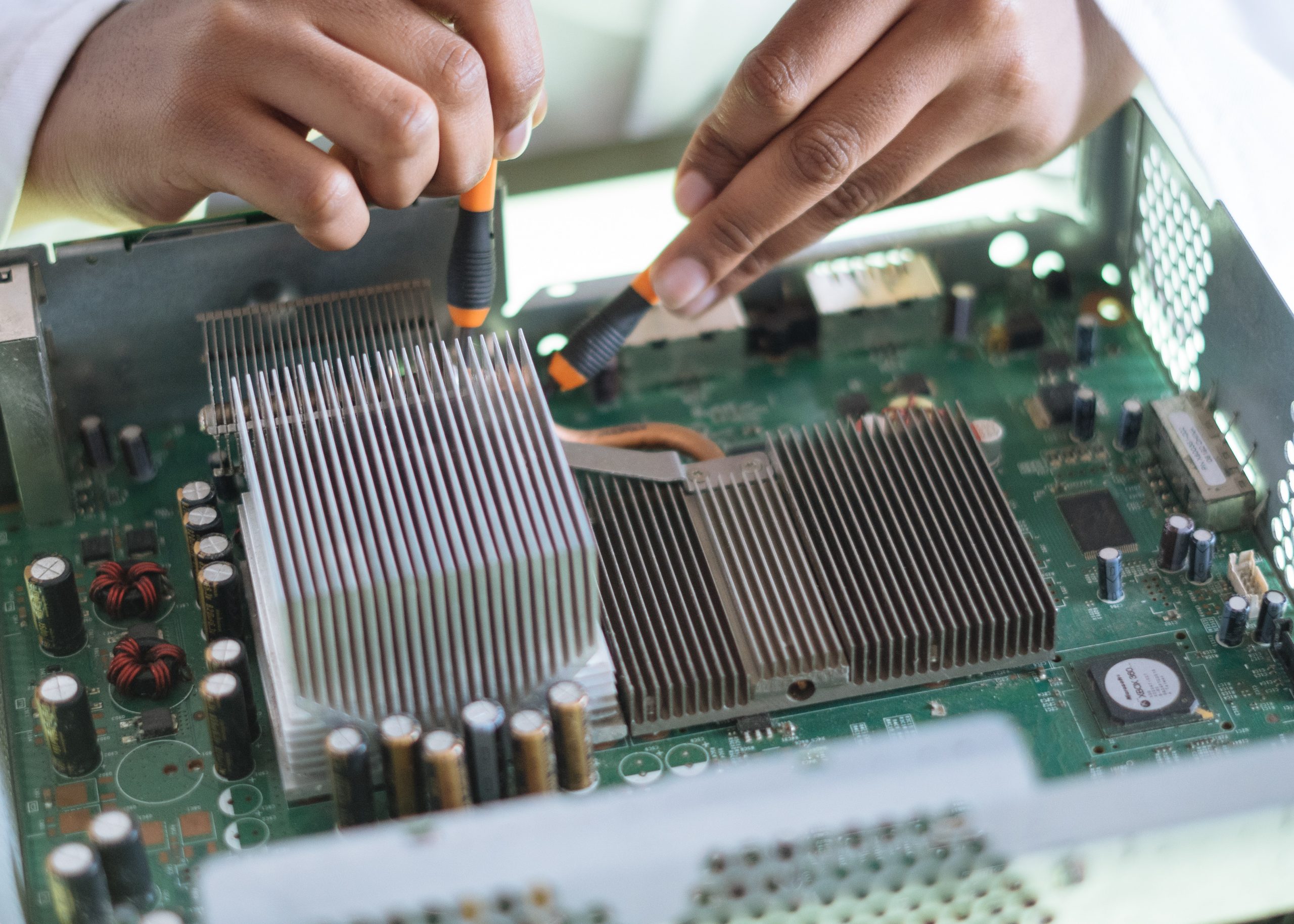

MANUFACTURING – HIGH TECH & ELECTRONICS

RFID-BASED ASSET TRACKING SAVES FORTUNE 500 HIGH-TECH LAB, $1M ANNUALLY

COMPLETE ASSET VISIBILITY FOR QUICK INVENTORY RECONCILIATION

INTHING VISIBILITY PLATFORM

IMPROVED IP PROTECTION, REDUCED ISO COMPLIANCE RISKS, IMPROVED BUDGETS

In the past, it took an average of 60 minutes to search our storage rooms for a sputtering target —and the odds of finding one were hit and miss.

Today it takes about five minutes to find the same part, with 99-percent accuracy..

Analysis shows that InThing IT Asset Visibility solution has already helped us avoid $125,000 in unnecessary expenditures.

This in the span of the last few months..

Murali Narasimhan

General Manager, Metal Deposition Products Group, Applied Materials

Overall, I’d estimate that tagVUE saves each of my group’s 100 or so lab users about two to four hours per week.

That would be 200 to 400 hours per week in total..

Murali Narasimhan

General Manager, Metal Deposition Products Group, Applied Materials

Solution Summary

Customer

Partner

Challenge

Solution

Results

The untraceability of critical high-tech lab equipment

Existing Challenges

♦ In 2010, the MDP group began looking for an Enterprise Asset Visibility solution to help it track the location of expensive consummables, the lack of which was causing the unproductive, labor-intensive search missions, which often led to the purchase of duplicate assets.

♦ Expensive assets were expensed instead of depreciated, thereby cutting into the annual engineering budget. A precious metal sputtering target costed upwards of $100,000, yet locating one required going from one storage location to another & without finding them, compelled the ordering of another item as an operational expenditure rather than searching for an existing one.

♦ Most existing RFID-based asset-tracking software provided basic asset location information, movement status, and elementary alerts and notifications. However, it was left upto them to customize the information to make critical business decisions, a time-consuming, costly and calculated effort for which they had no bandwidth.

Intervention of IT Asset Visibility

♦ InThing IT Asset Visibility Solution was chosen to provide accurate information on asset identity, status, ownership, location, and movement, using state-of-the-art sensor technologies such as RFID, Wi-Fi, Ultra Wideband (UWB), infrared, and ultrasound.

♦ InThing's Rapid Inventory System, Asset Reservation System alongwith two handheld RFID readers were used to tag, classify, and inventory over five weeks. Applied Materials was able to inventory 600 assets across its two buildings in just two hours.

♦ Custom antennas were designed and deployed to provide adequate coverage in the facility’s clean rooms and 8 RFID readers were mounted on doors—used together with InThing's Perimeter Control System to monitor the movement of assets in and out of specified areas. In the future, MDP plans to use InThing's Asset Visibility Solution together with its existing Wi-Fi network to track certain assets in real time.

Remarkable Turnaround on ROI

♦ Full asset visibility - MDP now has full visibility into capital and expense assets across its laboratory environment. The group can perform additional inventories or look up an asset in InThing's Asset Visibility platform at any time, with assets classified by specifications to improve identification and search capabilities.

♦ Increased Sharing and Lower Costs - MDP is already taking advantage of the solution to improve asset utilization and reduce the repurchase of existing components. 3 months after the solution went into production, the group had already prevented many unnecessary orders helping the company avoid $125,000 in unnecessary expenditures and forecasting $1M per year in total cost savings by tracking components.

♦ Fewer Labor-Intensive Search Missions - MDP employees no longer spend nearly as much time searching for assets. What took an average of 60 minutes to search storage rooms for a sputtering target, now takes about 5 minutes to find the same part, with 99-percent accuracy.

How InThing Asset Visibility Solution worked

➤ MDP deployed the InThing Asset Visibility solution, which runs on Windows Server 2008 R2, Microsoft BizTalk Server 2010, and Microsoft SQL Server 2008 R2.

➤ MDP was looking to address the following problems: Lack of visibility of all fixed assets which often led to minimal sharing of equipment and tool components, unproductive, labor-intensive search missions leading to the purchase of duplicate assets, expensive assets expensed instead of depreciated cutting into the annual engineering budget, unknown—and potentially unauthorized—movement of intellectual property and increased ISO compliance risks due to an inability to locate calibration equipment.

➤ InThing Asset Visibility was able to bring about full asset visibility for quick inventory reconciliation, reduced asset expenditures through increased sharing, 200 to 400 hours per week saved searching for assets, enhanced engineering budgets through conversion of OPEX to CAPEX, improved tracking of intellectual property and adherence to ISO calibration requirements.

Full asset visibility of sensitive high-value consumables across engineering labs

View Other Success Stories

Browse through the work we've done with clients, partners and businesses across verticals and industries.

PHILADELPHIA DEPT OF ELECTIONS

Philadelphia Department of Elections Adopts RFID To Automate the Tracking of Voting Equipment and Ballot Returns During Election. Zebra’s RFID readers and InThing’s Voting Equipment Tracking Software (VETS) transform the logistics and security of elections.

Know MoreSign up for subscription

Get started by contacting us today