Zero Errors

Reduces shipping errors (from 0.5% to 0%)

Surpassing 6-sigma Accuracy

Shipment integrated & validated at every step

Maintaining Chain of Custody

Reduces Disruptions owing to human error

TRUSTED BY INDUSTRY LEADERS

MANUFACTURING VERTICALS

InThing Connected Sensor Based Solutions are designed for a wide variety of goods and assets in the manufacturing industry

SEMICONDUCTOR

Wafer Tracking, Shipping Verification

AUTOMOTIVE

Material Audit

AVIATION & AEROSPACE

MRO Tools & Equipments

CHEMICALS

Chemical Containers & Equipment

DEFENSE & SPACE

IT Assets, Warehouses, Datacenters

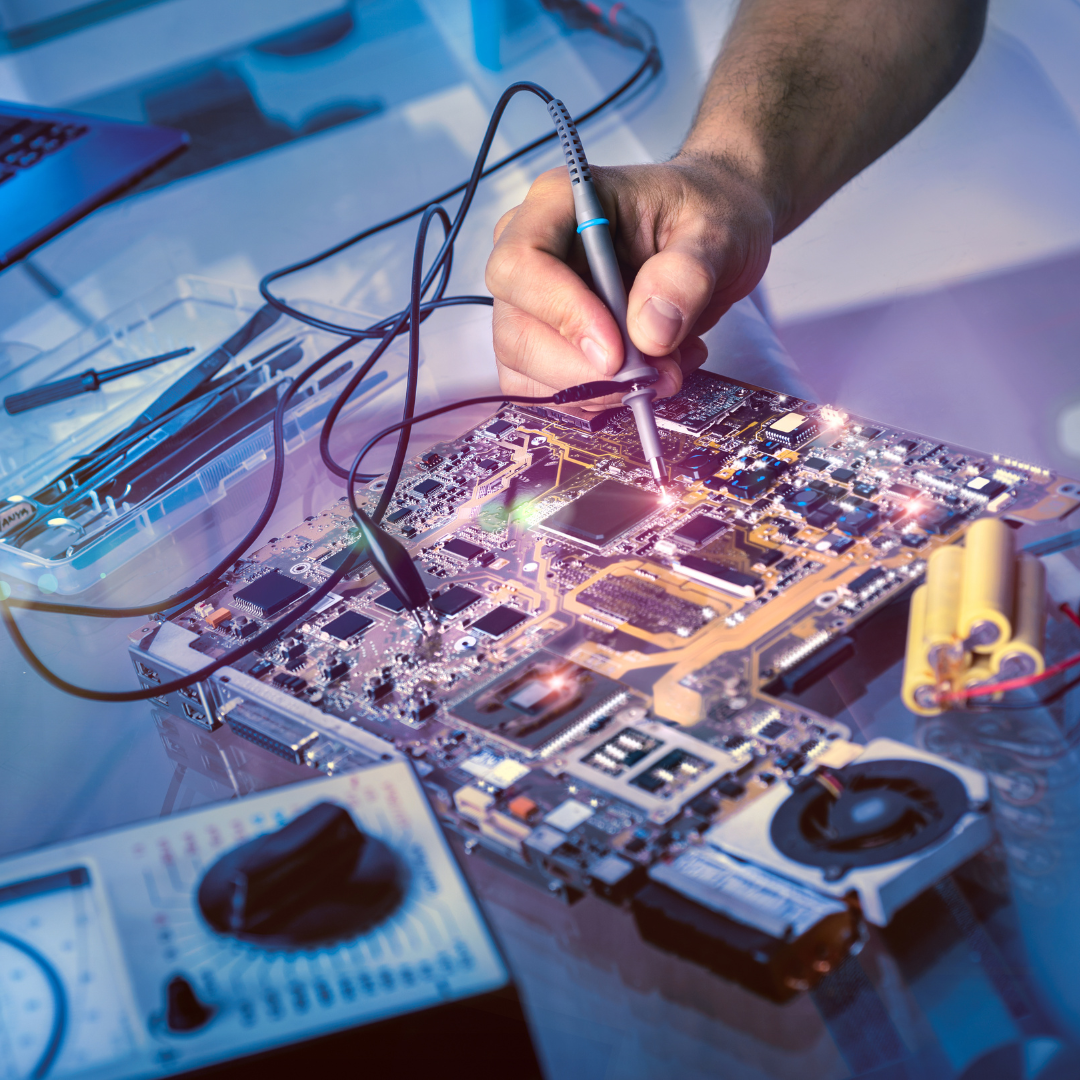

RFID IN MANUFACTURING

Keeping track of thousands of physical things at your warehouses and manufacturing operations is challenging. However, knowing where things are, is the first step and key to driving a number of transformations that can provide actionable insights in real time, impact productivity, deliver accuracies, and achieve overall operational intelligence.

Read Our Blogs

-

Automating Consignment Inventory With Sensor-Based Technologies

February 13, 2023Initiating consignment management capabilities can empower organisations across industries be near to their customers, ensure ready availability of materials, timely order fulfilment and improved efficiency across supply chains.

Read Story $ -

Transform the consumption model of your goods with consigned inventory

November 29, 2018If you have evaluated the benefits and pitfalls of having your goods at physical premises of your customer, not sold yet and still owned by you, the time has come to re-evaluate that assessment.

Read Story $

Sign up for subscription

Get started by contacting us today